Diesel merupakan salah satu mesin konvensi energi yang terjadi secara internal combustion dengan fluida kerja berupa udara yang tidak mengalami perubahan fasa saat proses masuk, terjadinya pembakaran hingga keluar sebagai udara buang melalui cerobong exhaust. Merangkum dari buku Thermodynamic karangan Yunus Cengel yang sering jadi acuan beberapa mata kuliah (bab 9 halaman 488).

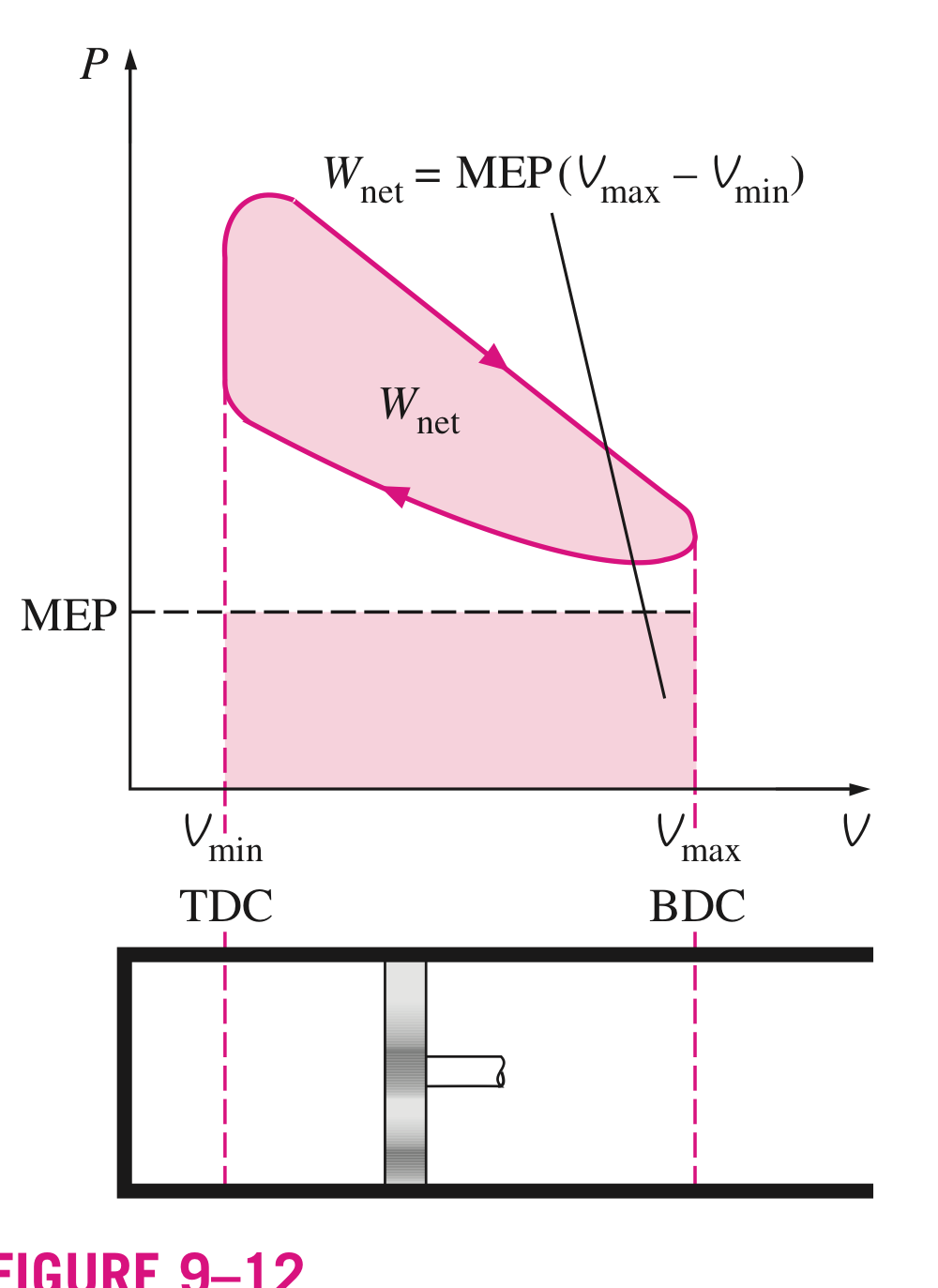

Salah satu jenis konversi energi dalam mesin pembakaran berjenis reciprocating atau bersifat bolak balik memiliki prinsip kerja ketika bahan bakar diumpankan kedalam ruang bakar dan tercampur dengan udara kemudian terkompresi energi (kimia) menjadi panas yang dapat menggerakkan secara mekanis suatu piston. Perubahan energi kimia (pembakaran) menjadi energi kinetik inilah yang dimanfaatkan untuk konversi energi yang dapat dimanfaatkan dalam proses berikutnya, apakah itu menjadi putaran roda ataupun menjadi penggerak generator untuk menghasilkan energi listrik.

Mesin diesel adalah salah satu jenis mesin konversi energi dengan prinsip recripocating secara pembakaran internal. Sedangkan fluida kerjanya adalah udara yang tidak mengalami peubahan fasa dan hanya mengalami perubahan secara volume maupun tekananya. Secara sederhana prinsip kerja mesin diesel dalam PLTD dapat dijelaskan sebagai berikut; perta bahan bakar dalam tanki bahan bakar misal MFO, HSD mapun B30 yang dialirkan dari daily tank dipompakan kedalam nozzle yang berfungsi sebagai pengabut yang menerima injeksi bahan bakar bertekanan tinggi dan temperature juga naik seiring kenaikan tekanan fluida. Supplai udara kedalam diesel dialirkan dari tanki udara melalui air intake system kemudian dialirkan melalui turbocharger untuk lebih mengefisiensikan dengan meningkatkan tekanan udara yang masuk. Turbocharger sendiri bekerja seperti mesin kompresi sentrifugal yang mendapat daya turbinnya dari gas buang. Tekanan yang dicapai udara mencapai 500 psi (34 bar) dan temperature 600 degC kemudian dialirkan ke ruang bakar secara simultan dengan aliran bahan bakar. Udara bertekanan dan temperatur tinggi yang masuk dalam silinder di ruang bakar akan membantu terjadinya self ignition dari bahan bakar ketika disemprotkan sehingga terjadi “ledakan” sehingga dapat menggerakkan torak yang dihubungkan dengan poros engkol oleh batang penggerak dan menyebabkan pergerakan secara rotasi poros rotor (generator) dan dikonversikan menjadi energi listrik.

Mesin diesel menggunakan prinsip reciprocating memiliki komponen utama yang berperan dalam mekanisme konversi energi seperti pada gambar berikut;